Advantages

Options

Pre-Washing Option

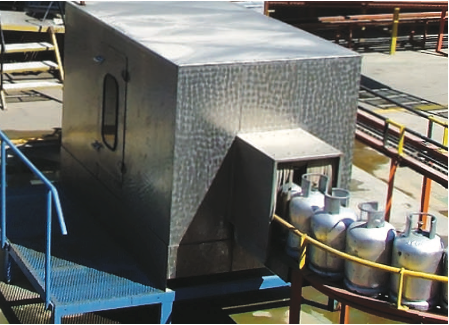

A pre-washing machine can be added to clean the residue on the cylinders that are difficult to clean.

Standard Cylinder Washing Machine Option:

Whlie the cylinders move on the conveyor line, the residue on the cylinder are cleaned with pressurized hot water. (Chemical or soap)

Brush Washing Option:

It offers a more in-depth cleaning option with rotating brushes applied to the surface of the cylinder. Number of brushes can be determined according to the needs of the facility.

Water Treatment Option:

The Oil Seperator Filter System will be used as an oil trap in the waste water, during cylinder washing.

It complies with DIN 4040 / DIN EN 1825 standards for the purification of wastewater from oils by rehabilitating the oil and derivatives that may be present in the water by undergoing appropriate processes before the liquids that may cause harmful and disturbing odor and damage the installation are given to the system.

Filter

Filtration is used to remove particles, turbidity and sediments in your water to give your water a clear appearance by filtering, etc. The system can be controlled volumetrically according to the amount of water passing through. Filter Process: Equipped with fully automatic control systems, this device, depending on the program to be given at the beginning, performs the necessary backwashing and rinsing processes in certain periods without the need for human intervention, in the service period, the particles filtered and kept between the filter layers are discharged in the backwash period and the filter material is cleaned and the media is renewed.

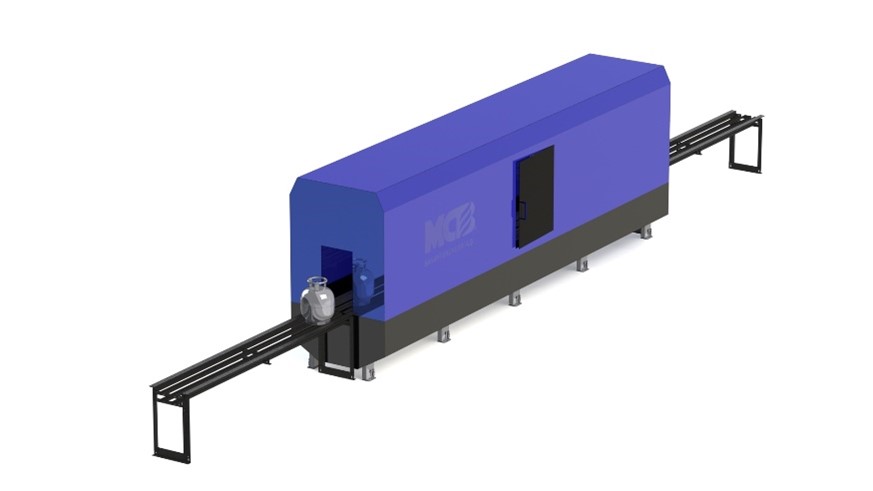

Cylinder Washing Machinecleans the outer surfaces of the cylinders while also ensuring efficient use of water, offering an environmentally friendly solution and reducing operating costs. Systems that can be customized according to the needs of the facility increase efficiency and improve safety and quality.

Contact us for more information and to find the best solution for your facility!